Discover the efficiency of the client-server architecture

Centralised data storage on the server and relieving the clients by having the server take over complex tasks means that hardware resources are optimally used.

The architecture supports parallel job processing, reduces costs by using several clients per server and enables flexible software usage thanks to floating licences. The client-server architecture is therefore a key to more efficient and cost-effective work processes.

MediaCheck

Modules

Discover our MediaCheck modules for efficient print image control.

MediaCheck Productivity

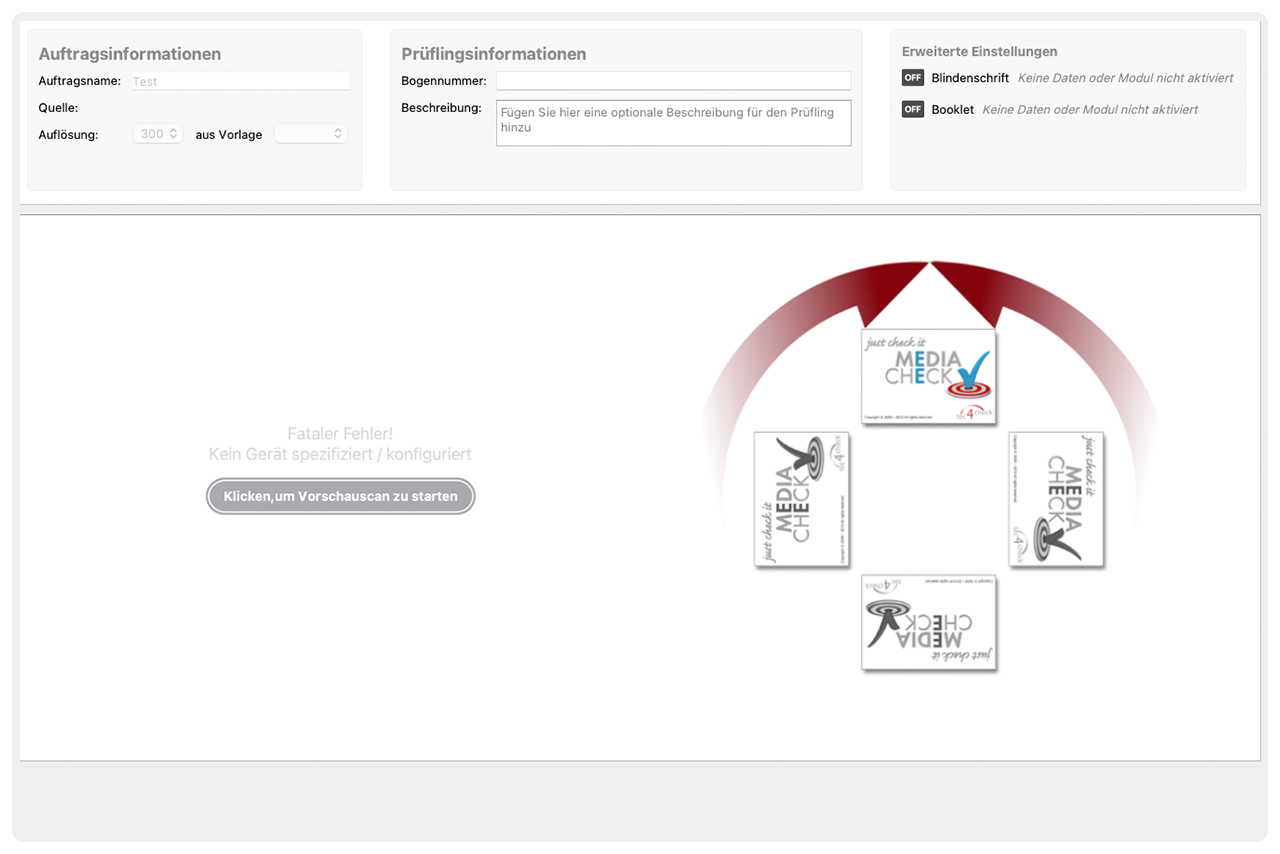

Increase productivity by automating your orders with template templates.

Braille/Blindenschrift-Modul

Decode and compare Braille from the PDF file and from the scanned packaging materials.

Booklet/Broschüren-Modul

With our booklet module, you can easily compare several pages from a PDF with a printed sheet or a full-page PDF in a single step.

MediaCheck Connect

Consolidate information from your workflow software such as ESKO to ensure seamless communication within your workflows.

Barcode-Modul

Integrate our barcode module into your quality assurance processes and ensure the reliability and readability of your barcodes.

Simple ScanStation

Print sheet inspection should take place as quickly as possible! On the other hand, quality assurance cannot be constantly manned or be at the printing presses.

Versatile areas of application

Discover the areas of application for our efficient print inspection.

Printing company

A print company wants to offer its customers the best possible quality. To achieve this, MediaCheck efficiently checks the printed products.

Pharma

As a pharmaceutical manufacturer, you carefully check the quality of your products and input materials, including printed packaging materials such as labels, leaflets and folding cartons.

Food and beverages

Constant changes to the legal requirements for information on the packaging of food and beverages.

Cosmetics industry

The information on ingredients must also be correct on cosmetic products. The importance of accuracy is increasing all the time.